Delivering high-performance COD and color removal with eco-friendly adsorption solutions

Introduction

Wastewater treatment is becoming increasingly important in industries such as textiles, chemicals, pharmaceuticals, and food processing. Among the available treatment options, powdered activated carbon (PAC) plays a key role in removing color, chemical oxygen demand (COD), and trace contaminants. But not all PAC is created equal — and wood-based PAC offers several advantages worth considering.

Why Use Powdered Activated Carbon in Wastewater Treatment?

Powdered activated carbon is widely used in:

- Color removal from dyes and pigments

- COD and BOD reduction in industrial effluent

- Adsorption of trace organics, pharmaceuticals, and persistent pollutants

PAC’s fine particle size allows it to disperse quickly in water, offering fast adsorption kinetics and effective removal in a short contact time.

Types of PAC: Wood-Based Activated Carbon vs. Coal-Based Activated Carbon

| Criteria | Wood-Based PAC | Coal-Based PAC |

|---|---|---|

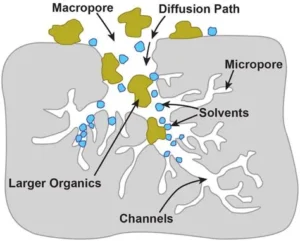

| Microporosity | Higher meso/macro pore ratio | Dominantly microporous |

| Adsorption Speed | Faster due to wider pores | Slower with narrow pores |

| Ash Content | Lower (typically <5%) | Higher (often 8–12%) |

| pH Stability | Mild, neutral | Often alkaline |

| Eco Profile | Renewable & biodegradable | Fossil-based |

Key Benefits of Wood-Based Powdered Activated Carbon

- ✅ Fast Adsorption: Rapid interaction with large organics due to wider pore distribution

- ✅ Low Ash Content: Less interference with downstream filtration or sludge disposal

- ✅ Easy Dosing: Compatible with DAF, coagulation, or biological processes

- ✅ Sustainable: Made from renewable biomass like sawdust and wood chips

Applications in Industry

- 🧪 Textile wastewater — Reactive, disperse, and direct dye removal

- 🏭 Chemical plants — Adsorption of complex COD and color

- 🍜 Food & beverage — Organic load reduction in soy sauce, gelatin, and starch effluents

- 🧼 Pharmaceutical & cosmetic — Removing trace organics and residues

How to Use PAC in Your Wastewater Process

- Add via dosing tank before or during coagulation

- Mix with flocculants (e.g. PAC + PAM) for improved removal

- Separate via sedimentation or flotation

- Dispose of spent sludge per local environmental regulations

Dosage typically ranges from 100–1000 mg/L, depending on COD level and pollutant type.

Why Choose Our Wood-Based PAC?

At HANYAN, we offer a range of high-quality wood-based powdered activated carbon products tailored for wastewater treatment, with customizable mesh sizes (200 mesh, 325 mesh), adsorption parameters, and packaging. Our technical team supports industrial OEM clients and environmental engineering projects worldwide.

Conclusion

If you’re looking for a sustainable and high-performing solution for industrial wastewater treatment, wood-based powdered activated carbon deserves serious consideration. Its rapid adsorption, low ash content, and compatibility with existing systems make it a top-tier option for COD and color removal.

Article Keywords: powdered activated carbon, PAC for wastewater, wood-based PAC, COD removal, color removal, dye wastewater treatment, food processing wastewater, eco-friendly activated carbon, PAC mesh size, wastewater adsorption