Natural sweeteners like erythritol and stevia glycosides have become increasingly popular in the health and functional food sectors due to their zero-calorie nature and plant-based origin. However, their raw extracts often contain color pigments, fermentation by-products, and odor compounds that must be removed to meet food-grade purity requirements. Wood-based powdered activated carbon is a critical purification aid in this process.

Understanding the Production Process of Natural Sweeteners

Erythritol is typically produced by fermenting glucose with osmophilic yeast or fungi such as Moniliella pollinis. After fermentation, the broth contains erythritol along with colored compounds, proteins, amino acids, and volatile impurities. Similarly, stevia extract is obtained by water or ethanol extraction of stevia leaves, followed by concentration. The resulting solution contains a mixture of steviol glycosides, chlorophyll, polyphenols, and bitter flavor compounds.

Before crystallization or spray drying, a purification step is required to remove unwanted color, odor, and taste components. This is where activated carbon treatment becomes indispensable.

The Role of Wood-Based Activated Carbon in Erythritol Refinement

In erythritol processing, activated carbon is introduced after filtration or ion-exchange but prior to crystallization. Properly selected wood-based powdered carbon helps:

- Adsorb yellow-brown pigments derived from Maillard by-products or sugar degradation

- Remove residual fermentation odors (e.g. ketones, aldehydes)

- Enhance product stability and whiteness, improving downstream crystallization

Recommended dosage typically ranges from 0.1% to 0.3% w/v depending on impurity levels. Mesh sizes of 200–325 mesh (74 μm and below) are preferred for high dispersion and rapid adsorption.

Purifying Stevia Extracts with Activated Carbon

Crude stevia extracts contain colored impurities such as chlorophyll, carotenoids, and polyphenols, as well as off-tastes often attributed to minor glycosides or leaf degradation products. Activated carbon treatment is applied post-extraction and before ion-exchange or chromatography steps.

- Removes green and brown tones to produce a clear liquid extract

- Adsorbs phenolic and oxidized bitter molecules

- Improves taste neutrality and sweetness perception

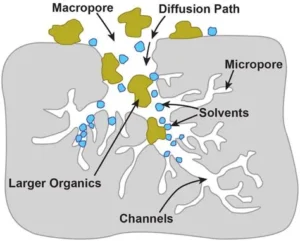

Wood-based carbon is ideal because of its high macropore volume, allowing effective capture of large organic molecules while maintaining low ash and high purity.

Why Use Wood-Based Powdered Activated Carbon?

- High purity: Meets food-grade specifications (low ash, acid-washed, no heavy metals)

- Efficient decolorization: Large surface area and pore structure tailored for color and odor molecules

- Dispersibility: Fine powder easily mixes with extract solutions for fast contact

- Sustainable source: Derived from renewable biomass like wood or sawdust

Compared to bone char or mineral-based carbon, wood carbon is plant-derived, non-animal, and generally recognized as safer for global food markets.

Best Practices for Sweetener Processors

To optimize activated carbon usage:

- Pre-filter solutions to reduce particle load before carbon addition

- Adjust pH (typically between 4.5–6.5) for maximum adsorption efficiency

- Use gentle mixing and appropriate residence time (10–30 minutes) before filtration

- Pair with fine filtration or membrane systems to minimize carbon residue

Trial tests at lab or pilot scale are essential to determine the best carbon grade and dosage for each sweetener system.

Partner with a Reliable Food-Grade Carbon Supplier

We offer wood-based powdered activated carbon specially formulated for the food industry, with proven performance in erythritol and stevia purification lines. All products are available with food-grade certifications and custom packaging options.

Contact us for samples, technical data, or application support.

Article Keywords: activated carbon, wood-based carbon, wood-based activated carbon, erythritol processing, stevia extract, sweetener purification, food-grade activated carbon, decolorization, odor removal