Table of Contents

- Introduction

- Why Treat Distillery Wastewater?

- How Activated Carbon Works in Distillery Wastewater Treatment

- Step-by-Step Process of Activated Carbon Treatment

- Performance and Benefits

- Future Applications and Market Potential

- Conclusion

Introduction

Distilleries generate wastewater rich in organic compounds like ethanol, proteins, and amino acids. If untreated, this effluent can negatively impact water bodies and the environment. Activated carbon adsorption has emerged as an efficient and eco-friendly method for removing these pollutants. This blog explores how activated carbon is used in treating distillery wastewater, its operational advantages, and the broader potential for sustainable water management.

Why Treat Distillery Wastewater?

The byproducts from alcohol production often include:

- High levels of organic matter

- Nitrogen compounds such as ammonia (NH₃), nitrites (NO₂⁻), and nitrates (NO₃⁻)

- Suspended solids and volatile substances

If not properly managed, these contaminants can harm aquatic ecosystems, corrode infrastructure, and compromise product quality. Regulatory compliance and environmental responsibility both demand effective wastewater treatment systems—and activated carbon offers an ideal solution.

How Activated Carbon Works in Distillery Wastewater Treatment

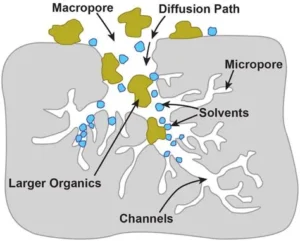

Activated carbon is a highly porous material with vast surface area and adsorption capacity. It captures dissolved organic compounds via:

- Physical adsorption within its microporous structure

- Chemical interactions with surface functional groups

To improve effectiveness, alkaline agents (e.g., sodium hydroxide) are added beforehand. This neutralizes acids and helps release bound organic molecules, making them more accessible to adsorption.

Step-by-Step Process of Activated Carbon Treatment

- Selection of Suitable Activated Carbon

- Choose types with high surface area and optimal pore structure for targeting complex organic pollutants.

- Pre-treatment with Alkaline Agent

- Add substances like NaOH to initiate neutralization and enhance release of organic load.

- Multi-stage Adsorption

- Wastewater passes through one or more stages of activated carbon beds.

- Each stage progressively removes organics until desired purity is achieved.

- Water Rinsing

- Post-adsorption rinse removes residual alkali and leftover impurities, ensuring cleaner discharge or reuse.

Performance and Benefits

✔ High Organic Removal Efficiency

- Lab results show organic removal rates exceed 95%.

✔ Improved Water Quality

- Significantly lowers COD, BOD, and nitrogen content, enhancing water clarity and safety.

✔ Reduced Effluent Discharge

- Enables partial or full reuse of treated water, contributing to water conservation.

✔ Lower Operating Costs

- More economical than many traditional chemical or biological treatments.

✔ Boosts Product Quality

- Helps maintain the purity and flavor profile of alcoholic products.

Future Applications and Market Potential

As consumer awareness of health and product purity increases, the demand for cleaner, greener alcoholic beverages is rising. Activated carbon-based treatment ensures:

- Consistency in production

- Minimal environmental footprint

- Compliance with food safety and environmental regulations

Beyond distilleries, this method shows promise in food processing, beverage bottling, and pharmaceutical wastewater treatment—where high purity and sustainability are top priorities.

Conclusion

Activated carbon adsorption is a powerful and practical solution for distillery wastewater treatment. By removing over 95% of harmful organic compounds, it not only protects the environment but also enhances product integrity and operational efficiency. Its scalability, simplicity, and affordability make it a go-to choice for any modern distillery looking to improve its sustainability credentials.

Article Keywords: Activated carbon distillery wastewater, Alcohol wastewater treatment, Organic pollutant removal, COD and BOD reduction, Sodium hydroxide wastewater pretreatment, Activated carbon adsorption process, Eco-friendly distillery operations, Industrial wastewater carbon filter, Brewery and distillery wastewater management, Sustainable alcohol production