Table of Contents

- Introduction

- Why Activated Carbon is Essential in Corn Oil Production

- How Activated Carbon Works in Corn Oil Filtration

- Economic Advantages of Activated Carbon Filtration

- Future Prospects and Technological Innovation

- Conclusion: A Cornerstone of Quality Corn Oil Production

Introduction

Corn oil, a globally popular edible oil prized for its flavor, nutritional value, and digestibility, requires meticulous processing to achieve high quality and stability. A critical step in this process is activated carbon filtration. This article explores the vital role of activated carbon in corn oil purification, its impact on production efficiency, and its evolving significance in the food oil industry.

Why Activated Carbon is Essential in Corn Oil Production

The corn oil extraction process inevitably yields unwanted impurities like waxes, proteins, and fibers alongside the oil. These contaminants compromise the final product’s stability, appearance, and taste. Activated carbon filtration addresses these issues by:

- Removing Organic and Inorganic Contaminants: Effectively adsorbing a wide range of impurities.

- Enhancing Clarity and Stability: Producing a cleaner, more stable oil with a longer shelf life.

- Reducing Undesirable Attributes: Eliminating color, odor, and residual polar compounds.

Integrating activated carbon filtration during the refining phase is crucial for meeting regulatory standards and satisfying consumer expectations for high-quality corn oil.

How Activated Carbon Works in Corn Oil Filtration

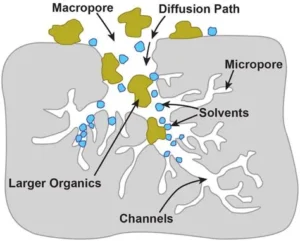

Activated carbon’s effectiveness lies in its highly porous structure and vast surface area, facilitating efficient adsorption.

- Physical Adsorption: Micropores and mesopores trap contaminants such as waxes, pigments, and trace proteins.

- Chemical Stability: Remains effective under the high temperatures and pressures of oil refining.

- Mechanical Strength: Durable material reduces replacement frequency and maintenance costs.

This robust mechanism ensures consistent impurity removal without affecting the corn oil’s nutritional profile.

Economic Advantages of Activated Carbon Filtration

Implementing activated carbon filtration offers significant economic benefits:

- Premium Product Quality: Cleaner, better-tasting oil with extended shelf life commands higher market value.

- Enhanced Process Efficiency: Reduces the burden on subsequent refining stages like bleaching and deodorization.

- Lower Overall Production Costs: Minimizes reprocessing, decreases energy consumption, and shortens production time.

- Cost-Effective Material: Activated carbon can be regenerated and reused multiple times, lowering raw material expenses.

Future Prospects and Technological Innovation

Driven by increasing consumer demand for healthier and purer oils, activated carbon’s role in corn oil production will continue to grow. Key future trends include:

- Advanced Carbon Materials: Development of nanostructured and composite filtration media for superior adsorption.

- Sustainable Sourcing: Utilizing eco-friendly raw materials like coconut shells and biomass for green activated carbon production.

- Intelligent Filtration Systems: Integration of AI and sensor technology for real-time monitoring and optimization of filtration performance.

These innovations will solidify activated carbon’s position as a vital component in producing safe, nutritious, and commercially successful edible oils.

Conclusion: A Cornerstone of Quality Corn Oil Production

Activated carbon filtration is indispensable for ensuring the purity, safety, and marketability of corn oil. Its ability to effectively remove impurities, enhance stability, and improve overall quality while offering economic advantages makes it a critical technology. For corn oil manufacturers aiming to meet stringent international standards and deliver premium products, investing in high-performance activated carbon filtration systems is a fundamental requirement.

Article Keywords: activated carbon corn oil filtration, corn oil purification, food-grade oil processing, improve corn oil quality, edible oil filtration, vegetable oil refining, reduce impurities in corn oil, sustainable oil production, oil refining with activated carbon, cost-effective oil purification, activated carbon uses in food, corn oil processing technology, edible oil quality control.