Diesel fuel, the backbone of transportation and industry, faces scrutiny for its sulfur content. These impurities harm the environment and hinder engine performance. Activated carbon adsorption emerges as a game-changer, offering a revolutionary method for sulfur removal in diesel.

Table of Contents

- Understanding Sulfur Impurities in Diesel

- Activated Carbon Adsorption: A Solution to Sulfur Pollution

- Adsorption Mechanism

- Benefits of Activated Carbon Filtration

- Industry Applications and Future Prospects

- Conclusion

Understanding Diesel’s Sulfur Problem

Sulfur, a natural contaminant in crude oil, finds its way into diesel. Upon combustion, it releases harmful pollutants like sulfur dioxide, contributing to air pollution and respiratory issues. Furthermore, sulfur can damage catalytic converters, increasing maintenance and reducing engine efficiency. Stringent regulations now limit sulfur content in diesel to address these concerns.

Activated Carbon Adsorption: The Sulfur-Removing Hero

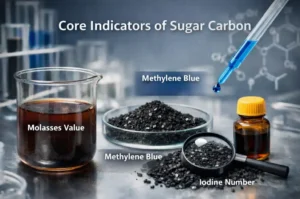

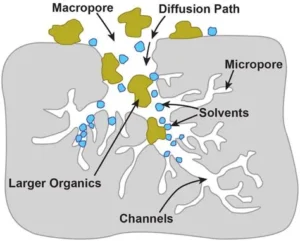

Enter activated carbon, a highly porous material with exceptional adsorption capabilities. It effectively removes sulfur compounds through two primary mechanisms:

- Physical Adsorption: Van der Waals forces and electrostatic interactions cause sulfur molecules to cling to the activated carbon’s surface.

- Chemical Adsorption: A chemical reaction bonds sulfur molecules directly to the activated carbon surface.

Benefits of Activated Carbon Filtration for Diesel:

- Exceptional Efficiency: Activated carbon filtration removes sulfur impurities with high efficiency, often achieving compliance with stringent regulations.

- Versatile Purification: It effectively targets various sulfur compounds present in diesel, providing a comprehensive solution.

- Cost-Effective Investment: While initial setup costs might be high, the long-term benefits outweigh the investment. Cleaner fuel translates to improved engine performance, reduced maintenance needs, and compliance with environmental regulations.

Industry Applications and a Sustainable Future

The petroleum industry is embracing activated carbon filtration systems in the diesel refining process. These technologies ensure regulatory compliance and deliver high-quality fuel. Ongoing research focuses on further enhancing efficiency and sustainability of these methods, paving the way for a greener and more economical future.

Conclusion

Activated carbon adsorption offers a revolutionary approach for cleaner diesel fuel. This technology aligns perfectly with global efforts to reduce emissions and enhance engine performance. As advancements in adsorption materials and techniques continue, activated carbon will play a vital role in promoting a sustainable and environmentally friendly future for transportation and industry.

Article keywords: activated carbon adsorption, sulfur impurity filtration, diesel purification, diesel quality improvement, environmental pollution control, engine performance, sulfur removal, fuel refining, sustainable energy solutions.