Decolorization plays a vital role in food processing, pharmaceuticals, beverages, amino acids, natural extracts, and many fine chemicals. Activated carbon is the industry’s preferred adsorbent for removing pigments and organic impurities. Among the various raw materials available, wood-based activated carbon and coconut shell activated carbon are the two most widely used.

Although both materials can achieve decolorization, their adsorption mechanisms, pore structures, and performance differ significantly. Understanding these differences helps manufacturers select the most suitable carbon type for their specific applications.

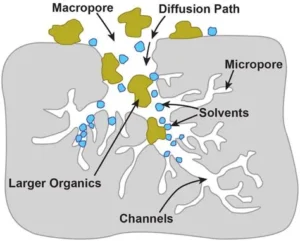

1. Differences in Pore Structure

1.1 Wood-Based Activated Carbon

Wood-based activated carbon typically features:

- Extremely rich macropores and mesopores

- High porosity and relatively low density

- Fast adsorption kinetics

These characteristics make wood-based carbon especially effective for:

- Removing medium- to large-molecule pigments

- Treating high-viscosity liquids such as syrups and herbal extracts

- Processes that require fast adsorption and high decolorization efficiency

1.2 Coconut Shell Activated Carbon

Coconut shell activated carbon typically features:

- A high concentration of micropores

- Very hard and mechanically strong structure

- Lower mesopore volume compared with wood-based carbon

It performs best for:

- Removing small organic molecules

- Solvent recovery and gas purification

- Water treatment and gold recovery applications

1.3 Pore Structure and Decolorization Performance

| Property / Performance | Wood-Based Activated Carbon | Coconut Shell Activated Carbon |

|---|---|---|

| Pore structure | Macropores + mesopores | Mainly micropores |

| Decolorization of large pigments | Excellent | Moderate |

| Adsorption speed | Fast | Medium |

| Performance in viscous liquids | Very good | Limited |

| Typical decolorization use | Food, pharma, fine chemicals, herbal extracts | Low-viscosity liquids, water treatment, combined purification |

2. Decolorization Performance in Real Applications

In actual production, decolorization efficiency is determined by how well pigments can enter the pores and interact with the carbon surface.

- Wood-based carbon provides more mesopores, allowing larger pigment molecules to diffuse easily, which is critical in high-viscosity or complex systems.

- Coconut shell carbon has a more “tightly packed” micropore structure that works well for smaller molecules but can be less efficient for bulky color bodies.

As a result, wood-based activated carbon usually achieves the same decolorization effect with a lower dosage and shorter contact time compared to coconut shell carbon in many liquid-phase processes.

3. Process Suitability: Where Each Type Performs Best

3.1 Wood-Based Activated Carbon – Ideal for Decolorization

Wood-based activated carbon is widely used in:

- Sugar and syrup refining

- Citric acid, MSG and organic acid production

- Pharmaceutical intermediates and APIs

- Amino acids and vitamins

- Herbal and plant extracts

These applications often involve complex mixtures and high-viscosity solutions. The rich mesopore structure and fast adsorption kinetics of wood-based carbon provide:

- Higher decolorization rate

- Better handling of large chromophore molecules

- More stable product color and clarity

3.2 Coconut Shell Activated Carbon – Strong but More Specialized

Coconut shell activated carbon is preferred when:

- Pigments and impurities are mainly small molecules

- High mechanical strength and abrasion resistance are required

- Applications combine decolorization with deep purification of water or solvents

- Processes demand multiple regeneration cycles (e.g., gold recovery)

In these scenarios, the high hardness and dense micropore structure of coconut shell carbon are advantageous, but in pure decolorization of viscous and complex liquids, it usually does not outperform wood-based carbon.

4. Cost and Operating Considerations

Besides technical performance, overall operating cost and process convenience are also important when choosing between wood-based and coconut shell activated carbon.

| Factor | Wood-Based Activated Carbon | Coconut Shell Activated Carbon |

|---|---|---|

| Typical dosage for same decolorization effect | Lower | Higher |

| Adsorption speed | Fast | Medium |

| Filtration behavior after use | Generally easier filtration and washing | May show higher filtration resistance |

| Mechanical hardness | Lower | Higher |

| Regeneration | Often used once in critical decolorization | More suitable for repeated regeneration in some services |

| Overall operating cost in decolorization | Usually more economical | May be higher for the same color removal target |

5. Which Is Better for Decolorization?

From the perspective of liquid-phase decolorization, especially in food, pharmaceutical and fine chemical industries, wood-based activated carbon generally provides a better balance of efficiency and cost. Its combination of micropores and mesopores enables:

- Higher color removal in a shorter time

- Better handling of high-viscosity and complex solutions

- Lower dosage to reach the same color standard

Coconut shell activated carbon remains an excellent material for applications such as water purification, solvent recovery, and gold recovery, where high hardness, deep microporosity, and multiple regeneration cycles are more important than handling large pigment molecules.

In summary:

- For most decolorization processes in food, pharma, and chemicals, wood-based activated carbon is the preferred and more efficient choice.

- For small-molecule removal, water treatment, and regeneration-intensive processes, coconut shell activated carbon may be more suitable.

Article Keywords: wood-based activated carbon, coconut shell activated carbon, decolorization, color removal, liquid-phase decolorization, food-grade activated carbon, pharmaceutical decolorization, pore structure, adsorption performance, mesoporous activated carbon