Wood powder activated carbon is a fine, highly porous adsorbent widely used for decolorization and purification across food, pharmaceutical, and chemical industries. Because of its strong adsorption and fine particle size, improper storage or handling can cause moisture uptake, cross-contamination, or dust explosion hazards. Use the checklist and procedures below to keep performance and safety at their best.

Contents

- Keep Away from Moisture

- Prevent Contamination & Cross-Adsorption

- Minimize Dust & Explosion Risks

- Apply FIFO for Consistency

- Packaging & Transportation

- Disposal & Regeneration Awareness

- FAQs

1. Keep Away from Moisture

Wood-based activated carbon is hygroscopic. Once pores are occupied by water, adsorption capacity for target molecules drops significantly.

- Store in a dry, ventilated warehouse with RH < 60% and temperature 5–30 °C.

- Keep away from water lines, steam, floor drains, or condensation-prone zones.

- After opening, reseal immediately (zip tie + inner PE liner) and return unused material to controlled storage.

| Control | Recommended |

|---|---|

| Relative Humidity | < 60% |

| Temperature | 5–30 °C |

| Air Changes | ≥ 3 ACH (non-condensing) |

Tip: Place data loggers near doors/aisles to catch humidity spikes during loading/unloading.

2. Prevent Contamination & Cross-Adsorption

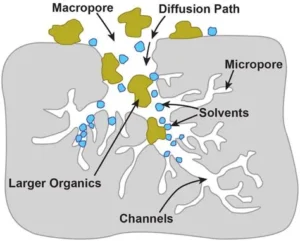

Activated carbon can adsorb odors, organic vapors, and fine dust from the ambient environment.

- Use airtight multi-layer bags (paper/woven + PE inner) or drums with gasket lids.

- Segregate from strong odors (solvents, oils, spices) and reactive chemicals (acids/alkalis).

- Do not mix grades or batches in one container; label batch/lot clearly.

- Use clean scoops, lined funnels, and dedicated transfer tools to avoid foreign particles.

3. Minimize Dust & Explosion Risks

Fine carbon dust can be combustible when dispersed in air. Control ignition sources and dust clouds.

- Ground all equipment, use anti-static containers and conductive liners.

- No open flames, hot work, or smoking in storage/handling areas.

- Use local exhaust/dust collection at transfer points; keep transfer height low to reduce agitation.

- PPE: at minimum respiratory protection, gloves, and safety glasses during transfers.

- Train staff on spill cleanup with vacuum systems (HEPA) rather than dry sweeping.

4. Apply FIFO (First In, First Out) for Consistency

Performance can drift over time, especially in suboptimal storage. FIFO keeps batches fresh and predictable.

- Label Production Date, Batch/Lot, and Net Weight.

- Use older stock first; avoid storage beyond 12 months in humid climates.

- Spot-check adsorption (e.g., methylene blue/iodine where applicable) for long-stored lots.

5. Packaging & Transportation

Integrity of packaging determines moisture protection and cleanliness during transport.

- 25/20 kg paper/woven bags with PE liners; for bulk, use jumbo bags.

- Stack on pallets, apply stretch/shrink wrap, keep off the floor and away from sunlight/rain.

- Avoid impact/crushing; use corner boards and top sheets to reduce dust formation.

- Document handling notes for the packaging and transportation (e.g., “Keep Dry”).

6. Disposal & Regeneration Awareness

Spent carbon may contain adsorbed organics or chemicals – manage responsibly.

- Follow local environmental regulations for classification and disposal.

- Consider thermal reactivation/regeneration for industrial volumes.

- Do not open-burn; control emissions via approved facilities.

FAQs

1.Q: What humidity is recommended for storage?

A: Maintain RH < 60% and 5–30 °C with regular monitoring. Reseal opened bags promptly.

2. Q: How do I reduce dust explosion risks?

A: Ground equipment, control dust with local exhaust, avoid ignition sources, and use HEPA vacuums for cleanup.

3. Q: Can I mix different grades?

A: Not recommended. Mixing can cause variability and cross-adsorption, complicating QC and process stability.

4. Q: What packaging should I choose?

A: 25 kg paper/woven bags with PE liners for standard use; jumbo bags for bulk. Always palletize and wrap.

Article Keywords: wood powder activated carbon, storage of activated carbon, handling activated carbon, activated carbon safety, moisture control, wood-based carbon, activated carbon warehouse, carbon dust explosion prevention