Wood-based powdered activated carbon (PAC) is widely used for decolorization in industries such as sugar refining, pharmaceuticals, and food processing. While iodine number is commonly used to measure the adsorption capacity of activated carbon, it does not always directly reflect its decolorization efficiency—especially in liquid-phase applications involving large organic color molecules.

What Is Iodine Number?

The iodine number (mg/g) is a standardized test that quantifies the ability of activated carbon to adsorb small molecules, typically around 10 Å in diameter. It is a reliable indicator of micropore volume and surface area—particularly useful for evaluating carbon used in gas-phase adsorption or removal of low molecular weight impurities.

Decolorization Efficiency: A Different Mechanism

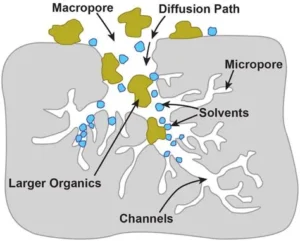

Decolorization primarily involves the removal of high molecular weight, often large-sized color bodies. These are usually too large to fit into the micropores measured by the iodine test. Instead, effective decolorization requires mesopores (2–50 nm) and macropores (>50 nm), which allow better diffusion and retention of dye and pigment molecules.

Why Iodine Number Can Be Misleading

- A carbon with high iodine number may lack the mesopores needed for color adsorption.

- Two carbons with similar iodine values can have vastly different decolorization efficiencies depending on their pore size distribution.

- High iodine number may indicate over-activation, which sometimes reduces structural strength and usable adsorption area.

How to Select the Right Wood Activated Carbon for Decolorization

When selecting activated carbon for decolorization, consider more than just the iodine number:

- Methylene Blue Adsorption: Better represents ability to adsorb larger molecules.

- Decolorization Ratio (%): Often tested using sugar liquor, methylene blue, or plant extracts.

- Pore Size Distribution: Mesoporous carbons with broader pore structures tend to perform better.

- pH and Surface Chemistry: Also impact adsorption of polar vs non-polar colorants.

Conclusion

While the iodine number is a valuable index for characterizing activated carbon, it should not be the sole criterion for evaluating wood-based carbon used in decolorization. A balanced approach—one that includes decolorization tests, pore analysis, and real-world liquid-phase performance—is key to selecting the most efficient product.

Looking to customize decolorization carbon for your application? Our engineers can tailor solutions based on your raw material, colorant type, and process needs.

Keywords: iodine number, decolorization efficiency, wood-based activated carbon, liquid phase adsorption, color removal, PAC, powdered activated carbon, methylene blue test, pore size distribution