Wood-based powdered activated carbon is a go-to choice for decolorizing liquids in the food, pharmaceutical, and chemical industries. However, its performance is highly dependent on a variety of process and material parameters. Understanding these factors is crucial for optimizing results while minimizing cost and product loss.

1. Pore Structure and Surface Area

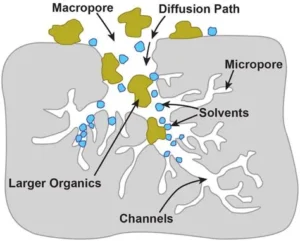

Wood-based carbon typically contains more mesopores compared to coconut or coal-based carbons, making it ideal for removing large molecules like caramel, melanoidin, and plant pigments. BET surface area and mesopore volume are key indicators—more reliable than iodine number alone when evaluating decolorization capacity.

2. Particle Size and Mesh Distribution

Finer mesh sizes (e.g., 200–325 mesh) provide greater surface area and faster adsorption, but may slow down filtration or cause clogging. A balanced particle size offers efficient adsorption with manageable filtration properties. Custom mesh cuts can be used to suit specific equipment setups.

3. Optimal Dosage and Contact Time

Overdosing activated carbon doesn’t always improve color removal and may increase filtration costs. Pilot testing helps determine the optimal dosage based on the type and concentration of colorants. Typical contact times range from 20–60 minutes with continuous stirring to ensure effective contact.

4. pH and Temperature of the Solution

Acidic conditions (pH 3–5) often enhance pigment adsorption. Higher temperatures accelerate diffusion and adsorption rates but may reduce capacity if too high, leading to partial desorption. Temperature optimization is essential in heat-sensitive applications like enzyme or vitamin production.

5. Presence of Competing Substances

Proteins, polysaccharides, and other dissolved organics may compete with pigments for adsorption sites. Pretreatment using clarification, filtration, or enzyme degradation may be necessary to enhance color removal by activated carbon.

6. Quality of the Activated Carbon

For sensitive applications, only food-grade or pharma-grade carbons should be used. Low ash, acid-washed, and certified materials (e.g., FCC, USP) help prevent contamination and meet regulatory standards. Impurities can interfere with adsorption or leach into the treated liquid.

7. Filtration Equipment and Process Compatibility

The efficiency of carbon removal after adsorption depends heavily on the filtration system used—filter presses, centrifuges, or bag filters. Selecting compatible carbon grades helps avoid excessive pressure drops or residual carbon in the final product.

Conclusion

Decolorization using wood-based powdered activated carbon is not a one-size-fits-all process. Fine-tuning variables such as pore size, mesh, dosage, pH, and temperature can significantly impact performance. By understanding and controlling these factors, industries can achieve better efficiency, lower costs, and improved product clarity.

Article Keywords: wood activated carbon, powdered activated carbon, decolorization efficiency, food grade carbon, liquid purification, iodine number, particle size, pH, adsorption, mesh size